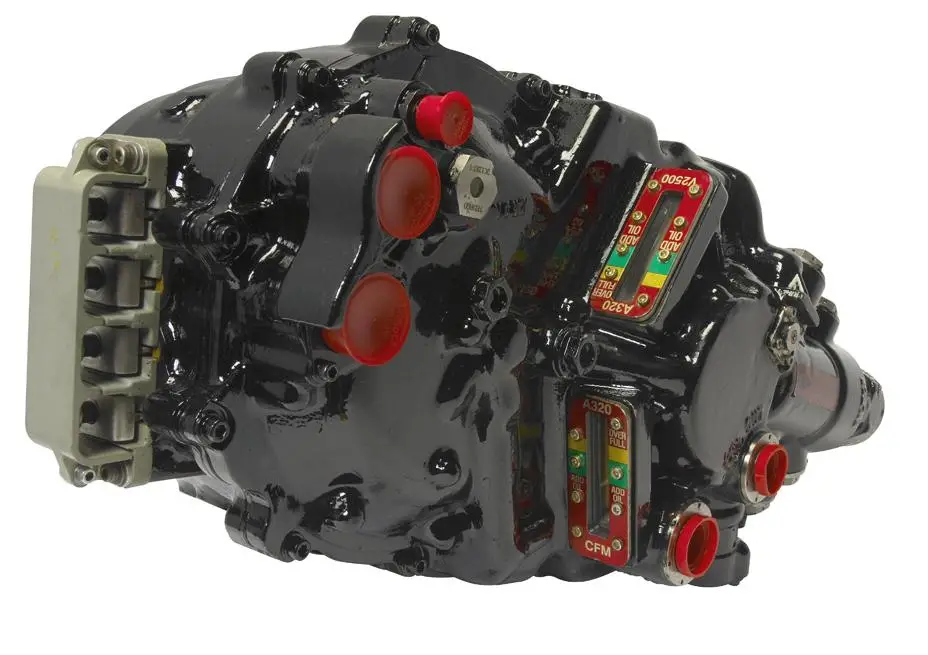

IDG ( integrated drive generator) is a Electrical generator which provides Electricity for the Aircraft. IDG provides electrical power for All the aircraft systems. It consists a generator and a Constant Speed Drive (CSD).

The generator uses the kinetic Energy of the Aircraft Engines and convert it into Electrical energy.

CSD coverts variable input of the engine into a fixed rotational speed for generator. So, the Generator can provide a fixed frequency to the Aircraft Electrical network.

Oil, a hydraulic fluid, is one of the vital components of the IDG. Oil is used for cooling and lubrication, and is also used to by the CSD to regulate the rotation speed of the generator mechanically.

IDG is driven by the engine Accessory Gearbox. It is Accessible in the Engine Nacelle. The reliability and the efficiency of the IDG is depended on the cleanness and correct Quantity of the OIL Used. Oil level is controlled by the sight glass, which indicates the oil level. Cleanness of the Oil is ensured by taking some precaution, As described in the Aircraft Maintenance Manual.

Contamination of the Oil with water or dust can cause premature filter clogging — excessive wear IDG and overheat condition. Oil cans and tools should be kept in clean and dry environment. It is preferable to use a new can of Oil when you service the IDG.

IDG oil systems consist of.

1.IDG.

2.External Cooling Circuit.

3.IDG oil cooler.

let us take a look at how the Oil circulate in the IDG oil system.

During operation, Oil is pumped out of the IDG to be cool down in the cooler. And the cool Oil comes back into the IDG.

During servicing, the oil is pumped through the IDG pressure Fill port. It goes through the IDG filter and Exits the IDG into the External Circuit. Flows through the external circuit, circulates into the cooler, flows through the external circuit, and comes back to the IDG case. now the IDG case is filled with Oil. once the Oil exceeds the top of the overflow standpipe; it flows outside the IDG, through the overflow drain port. Top of the overflow standpipe, corresponds to the top of the green band of the sight glass.

The aim of the Servicing procedure is Aimed at filling all the cavities of the IDG circuit with Oil, expelling Air pockets, thus setting optimum oil level. If there are too much oil in the IDG, the operating temperature increases, and there is a risk of an IDG disconnection in flight. a low quantity of oil, maybe at the origin of a low oil pressure, and electrical frequency fluctuation. the generator may be lost in flight.

after correct servicing, the optimum oil level is at or near the top of the green band.

Some Aircrafts comes with oil level sensor. if the oil level at the lower part of green band, low oil level detection maybe generated in operation. light may be indicted. this will create extra burden for maintenance and flight crew.

Read caution notes and Follow Aircraft Maintenance Manual Step by Step. Ensure that the Entire IDG oil System is properly Filled with Oil and All air pockets are expelled.

IDG systems are covered in EASA part 66 Module 11 A, In Electrical systems ATA 24. honeywell is one of the major producer of Aircraft IDGs.

IDG OIL SERVICING

Reason for the IDG Servicing can be,

- Fill an Integrated Drive Generator (IDG) installed on aircraft you drained it.

- Fill replacement IDG installed on the aircraft.

- Add oil when the oil level at the sight glass is not correct.

- Add oil after replacement of the scavenge filter element.

- Add oil after replacement of a component of the IDG-oil cooling system.

Before you service IDG.

WARNING: BE CAREFUL WHEN YOU WORK ON THE ENGINE COMPONENTS IMMEDIATELY AFTER THE ENGINE IS SHUTDOWN.

THE ENGINE COMPONENTS CAN STAY HOT FOR UP TO ONE HOUR.

WARNING: WEAR GOGGLES, INSULATED GLOVES AND OTHER PROTECTIVE CLOTHES. HOT OIL CAN BURN YOUR EYES AND

SKIN. IF OIL TOUCHES YOUR EYES OR SKIN, GET MEDICAL AID.

CAUTION: DO NOT OPERATE THE IDG:

◦ IF IT CONTAINS TOO MUCH OIL.

◦ IF IT DOES NOT CONTAIN ENOUGH OIL.

IF YOU DO, YOU CAN CAUSE DAMAGE TO THE IDG.

CAUTION: USE ONLY NEW CANS OF OIL WHEN YOU FILL THE IDG WITH OIL OR ADD OIL TO THE IDG. THE CONTAMINATION IN OIL.

THAT STAYS IN OPEN CANS CAN CAUSE FAST DETERIORATION OF THE OIL AND WILL DECREASE THE LIFE OF THE IDG.

CAUTION: REMOVE THE REMAINING OIL FROM THE FILLING EQUIPMENT. FILL THE EQUIPMENT ONLY WITH NEW CANS OF

OIL BEFORE YOU FILL THE IDG WITH OIL OR ADD OIL TO THE IDG. THE CONTAMINATION IN THE OIL THAT STAYS IN THE

FILLING EQUIPMENT CAN CAUSE FAST DETERIORATION OF THE OIL AND WILL DECREASE THE LIFE OF THE IDG.

CAUTION: DO NOT USE SOLVENTS THAT CONTAIN CHLORINE TO CLEAN THE EQUIPMENT ( Like PUMP, HOSES, TANK AND FUNNEL) which are USED TO FILL THE IDG WITH OIL. CHLORINE CONTAMINATION OF THE OIL CAN CAUSE FAST DETERIORATION OF THE OIL AND WILL

DECREASE THE LIFE OF THE IDG.

CAUTION: USE ONLY APPROVED TYPES/BRANDS OF LUBRICANTS. DO NOT MIX TYPES or BRANDS OF LUBRICANTS.

CAUTION: DO NOT DO THE SERVICING OF A DISCONNECTED IDG.

CONTINUED OPERATION OF A DEFECTIVE IDG CAN CAUSE DAMAGE.

Tools required,

CONTAINER 10 Liters.

- 1 FILLING EQUIPMENT – TANK OIL,

- DRAINING HOSE.

- AR WARNING NOTICES.

- IDG OIL CANS.

Job Set-up.

Energize the ground service network.

Safety Precautions.

Put a WARNING NOTICE On the center pedestal, to tell persons not to start the engine.

Make sure that the Servicing engines shutdown occurred not less than 5 minutes, before you do this procedure.

On the overhead maintenance panel 50VU,

Make sure that the ON legend of the ENGINE/FADEC GND PWR pushbutton switch is off.

Put a WARNING NOTICE in position to tell persons not to energize the SErvicing Engines FADEC.

place a container under the IDG to collect the Oil the overflow during the servicing. remove the dust cap from the overflow drain port. connect the overflow drain hose, on the overflow drain port. this Action will depressurize the IDG. some oil may come out from the overflow drain hose. ensure the tube is not bent and the end is not immersed in the Oil.

Depressurization of the IDG Case.

WARNING: POINT THE OVERFLOW DRAIN HOSE INTO A CONTAINER WHEN YOU CONNECT THE HOSE TO THE OVERFLOW DRAIN HALF-COUPLING. THIS WILL PREVENT BURNS FROM THE HOT OIL SPRAY. HOT OIL CAN CAUSE BURNS TO EYES AND SKIN.

CAUTION: DO NOT USE DEVICES OTHER THAN THE APPROVED OVERFLOW DRAIN-HOSE FITTING. HARD METAL OBJECTS SUCH

AS SCREWDRIVERS CAN CAUSE DAMAGE TO THE OVERFLOW DRAIN HALF-COUPLING SEAT.

remove the dust cap from the pressure fill port. connect the pump on to the pressure fill port. Fill the IDG with the Oil with the maximum of 35 PSI. ensure there is enough Oil in the reservoir in order to avoid the introduction of the Air in the IDG system. use a transparent tube to control the condition of the Oil during the ODG filling.

During the servicing, the Oil enters the pressure fill port, enters the filter, flows through the external circuit, and circulates into the cooler, flows through the external circuit, and comes back into the IDG case.

keep pumping till the IDG CASE is filled with Oil.

once the Oil exceeds the top of the overflow standpipe, it flows outside the IDG, through the over flow drain port. keep pumping to fill the entire circuit, and expel air pockets from the system. stop pumping, when the quantity of Oil collected at overflow container exceeds more than a liter or one us Quart. oil will continue to overflow until, the level of Oil is drop down to the top of the overflow standpipe. while the Oil is overflowing, remove the pressure fill hose.

install the dust cap on the pressure fill port.

when the oil level reaches the top of the overflow standpipe level, the oil stabilizers at its optimum level at top of the green band. when only drops of Oil comes out of the overflow drain, disconnect the overflow drain hose, and install its dust cap on the over flow drain port.

Before singing Off

do an Engine dry motoring, or start the engine at idle, for at least two minutes.to Allow the engine to circulate, through the system, and ensure every cavity in the oil system is properly filled with Oil. let the oil level settle down for 5 minutes. the oil level might be slightly above the top of the green band, due to thermal OIL expansion. however, the oil level maybe dropped., due to presence in the air in the system before the motoring.

look at the oil level sight glass again to ensure that the oil level is optimum.

CAUTION: IF YOU DRY-MOTOR THE ENGINE, MAKE SURE THAT THE OIL LEVEL IS STABLE BEFORE YOU DO THE INSPECTION.

THE OIL LEVEL WILL BECOME STABLE ONLY AFTER 30 MINUTES.

THUS, THE LEVEL INDICATIONS ON THE SIGHTGLASS WILL NOT BE CORRECT BEFORE THE END OF THIS PERIOD. IF YOU ADD OIL

WHEN IT IS NOT NECESSARY, THERE IS A RISK THAT YOU WILL CAUSE FAILURE OF THE IDG.

good servicing is very important as it contributes to the good performance of an IDG.